Background and Motivation

I love my Wemacro Micromate, but similar to everything in life, improvements can be made. The original system aims to be universal, reliable, while also keeping the cost within an acceptable range. For amateur photomicrography photographers, there exist no other choice that is reasonably priced. To put everything into perspective, the cost of the Micromate system (motor frame and controller) is the same as a used Prior joystick for advanced industrial microscopy automation devices. Companies such as Prior (England) and Märzhäuser Wetzlar (Germany) offer such systems, while each offering economically conscious models, the prices are still forbiddingly high, even in the used market.

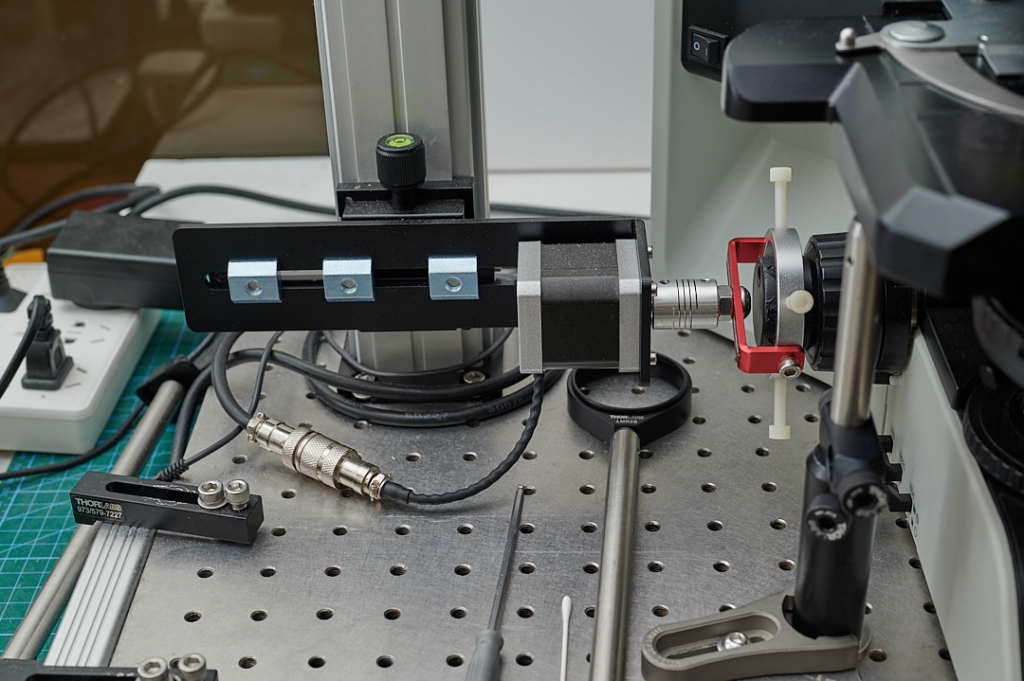

My main grievance with the Micromate is the coupling method, four nylon screws are used, which becomes loose over time and must be meticulously aligned to avoid instability. The frame is very basic and must be clamped down, however, this is not an option since I work on an optical table. My first improvement to the device is captured by a couple hundred dollars spent on some nice Thorlabs components. I constructed my own frame with 2 degrees of secure adjustments (X and Z).

This worked out nicely. Despite the lacklustre coupling method, this is a major improvement that solved all the small issues I have encountered. I can align the coupling ring perfectly and slide it out when I want to use the left hand focusing knobs of my microscope. At the heart of this revised stand is an Arca-Swiss compatible rail offering the convenience of clamping. The rail is secured to the motor bracket via 1/4”-20 T-slot sliders and longer Arca-Swiss plate screws.

A new problem presented itself. Inevitably, the microscope is no longer centred on my optical table bench. Since I mainly work on the right side, a lot of real estate is now wasted. I would like to mount a digital gauge indicator onto my microscope stage, on the right, which can no longer be achieved. My ideal solution would be a large tube mounted onto the larger curled coarse focusing knob, which a motor slid in to mate with the fine focusing knob, offering the same focus stacking capabilities, but hanging off the large knob. This should in theory address every single problem I have. No more centring headaches, more space, and cleaner looking.

Luckily, Prior Scientific offers exactly what I was looking for.

This device is incredibly simple yet effective, it works for microscopes offered by the ‘big 4’, and their corresponding clones. A device like this would probably cost thousands if purchased new, the used market is home to a myriad of them, and similar models from other companies. I hunted a copy down for $60. I have seen them ending for as low as $20 in auctions. My task is thus figuring a non-destructive adaption method. The motor type must be the same as Wemacro’s, preferably with a similar current rating so the stepper motor will not turn into a graphics card being used for crypto-mining, essentially an egg fryer.

Disassembly

This section is for those interested in the construction of the device. Disassembly of the unit is not needed at all, the adaptation is as simple as running 4 jumper wires.

To disassemble this unit, the tools illustrated above is required. A Philips slotted screwdriver (PH00), a 2mm hex screwdriver (a hex wrench did not work well for me), and a magnetiser. Some thermal paste is displayed here and I will explain later.

Start by loosening the curled knob grubbing screw, this will release the motor’s housing, pull it out. Flip it over and remove the three small slotted screws. Do not touch the large one in the centre, it does not matter (it is used for grounding).

Illustrated here, my unit arrived with a missing screw. I will have to find one as a replacement.

Put the motor housing on the side, you will see an open through-hole. Rotate the motor manually and find yourself the slotted screw, loosen it and pull out the rubber drive bush. My unit had some rust, so I had to pry it out with a clamp.

Now, loosen the 4 2mm hex screws. I performed this step first and it was slightly harder to remove the rubberised driver bush. One of my screws are missing here because it was heavily damaged. I had to hammer in a cheap hex screwdriver and twist it out, the screw was crooked and evidently forced in during assembly. I think most of the cost here is Research and Development for their controller box, modules, and their software. I will buy a replacement screw.

The device is incredibly basic, yet effective. The core of this focusing drive is a “4318S-01B 1A” motor bipolar two-phase stepper motor by Lin Engineering. Absolutely no information can be found on this model, indicating it to be some kind of custom, non-standard special part. Better not set the coils on fire. Due to the lack of documentation, I do not know the pin-out for this motor, neither do I know its current rating. An educated guess would be 1A due to the marking. In the part number, “18” indicates that the motor has a 1.8° Step Angle, “S” probably means small, “43” indicates a frame size of likely 17, making it a “NEMA 17” type motor. The output current of the Wemacro controller is 2.5A, a bit too high for me to be 100% comfortable. The motor is going to heat up rather quickly. I will explore ways to modify the controller so the output current is lowered.

Making the Adaptor

The focus drive’s connector is some kind of male RS232 DB9 block. There are only 4 cables, so 5 of these pins are vacant and probably grounded.

I pulled the plug apart, only 4 pins are used of course.

I have no datasheet, so I do not know the pinout of this connector. Messing the pins up could set the controller on fire. Luckily, my extensive electrical engineering degree (didn’t, learned this trick from a friend, we were taught a %$&@ load of theory only) taught me how to use a multimeter. Setting the device to the beeper which measures connectivity allowed me to easily extrapolate the pinout.

So, here is the diagram.

For the Wemacro controller, the pinout is similar. You will see numbering on the back of the male connector, 1 and 2 (same phase), 3 and 4 (same phase) represents the phase coupling.

I was able to guess the direction of the motor from Prior’s documentation.

“If the left hand coarse control knob is preferred by the user or the focus drive is to be mounted on an inverted microscope, the motor direction can be reversed by using a PC with a terminal emulation programme e.g. Prior Terminal and changing the settings of the ZD command (see section 6) via RS232 communication.”

No programming is needed here, simply swap one of the phases will reverse the rotation of the motor. I will be mounting the focus drive to the left hand side. My connection was pins 1, 6 on the DB9 connector to pins 1, 2 on the Wemacro (transporter-space) male plug. Pressing “forward” on my phone should rise the stage, “backward” will lower it, that is what I aimed for.

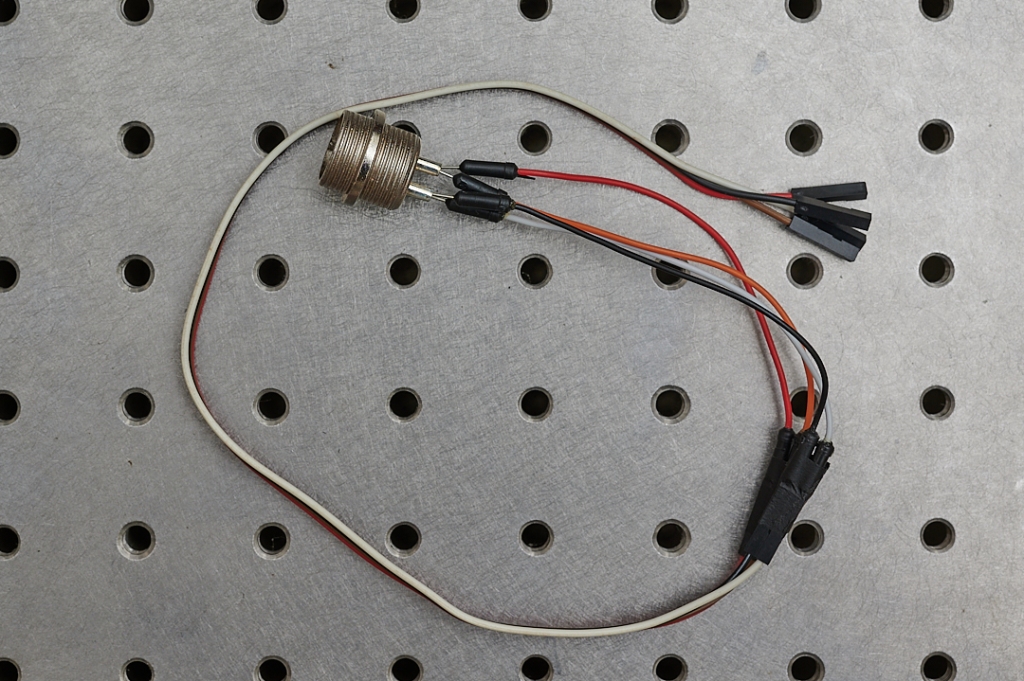

My 5-minute adaptor is finished. I pulled some cheap female-female and male-male jumper wires from my crusty university ‘lab junk box’ to make a female-male wire, and soldered it onto the plug while I was eating dinner. In Part 2 of this series, I will be making a proper adaptor plug using a DB9 connector.

Reassembly

As expected, the motor became very hot after minutes of running. The motor shell is a heatsink in itself. To dispose the heat more efficiently, I decided to coat it with some thermal paste. Use a decent branded one here, cheap thermal paste does the opposite of transferring heat and could solidify, even becoming conductive!

The frame of the focus drive uses one of these tiny knob screws that trigger me. I dislike these silly curled grub screws, the knobs are too small and painful to use, it is impossible to control the torque. Why should I deal with that when I have torque drivers? I replaced the original screw with a nylon tapped 2mm hex set screw (M4).

Reversing the disassembly process, the focus drive is reassembled (well, of course!).

Installation

I applied one layer of gaffer tape onto both focusing knobs. I suggest removing the nosepiece and stage of the microscope during installation. This makes tightening the screws easier and avoids unwanted damage.

I followed the steps outlined in Prior’s documentation (see references). Basically, push the frame into the desired coarse focusing knob, secure the set screws gently (preferably with a torque driver), make sure the frame rotates as you engage the non-occupied coarse focusing knob. Then, simply push the motor housing into the frame, make sure the rubber drive bush mates with the fine focusing knob adequately, and tighten it with the silly curled knob screw, or in my case, use a 2mm hex screwdriver (I replaced it, shown above).

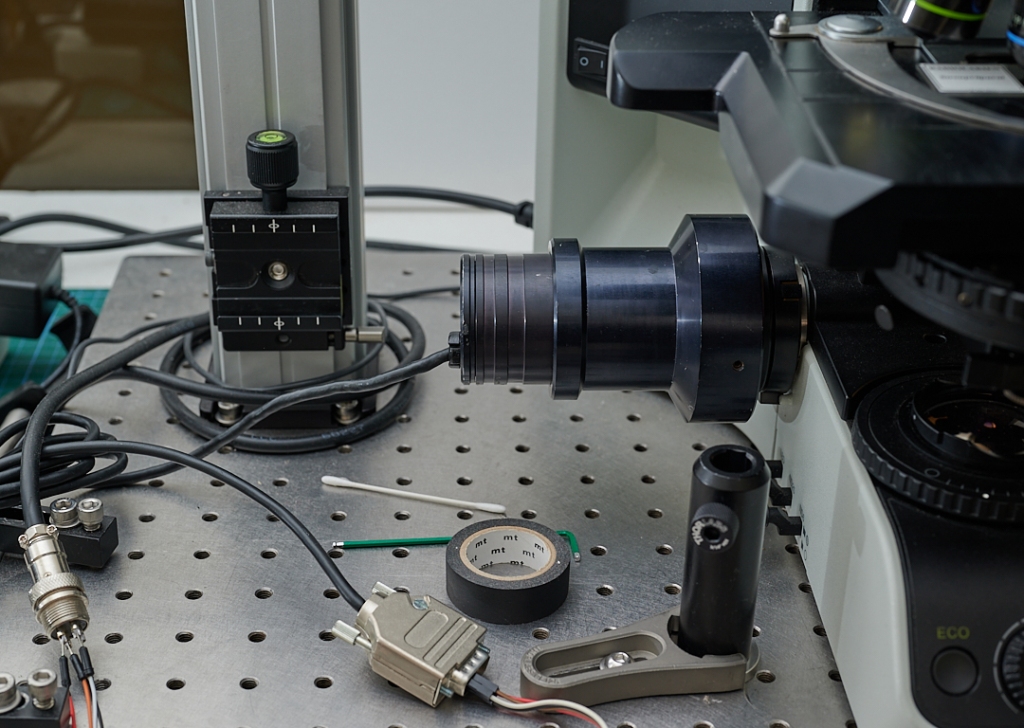

Here is the result!

Now, I can tidy up the table, move the microscope to the centre of the optical bench, remove the optical rail block, and deal with the messy cables. Powering the Wemacro controller, I can now hear a faint squeal which is very annoying. Setting the Stackshot controller to high resolution mode produces a very similar sound. Perhaps lowering the current output of the controller will solve this problem. The motor housing does not heat up to a point which it is untouchable. This means the heat is being distributed nicely.

In Part 2, I will assemble a proper adaptor and potentially explore ways to lower the controller’s output current.

The Cost

Presumably, the Wemacro controller is $80. The Wemacro Micromate package is $229 and the “frame only” package is $149, deducting the two gives $80. The used Prior Z-axis focus drive was $60. With shipping costs being considered, I spent a total of around $180 on this system, $200 at most. This does not include my previous attempts to improve the Micromate.

Results

I ran a couple of stacks, the motor housing never got too hot. This motor is speedier than Wemacro’s original despite using the same controller, that is another welcomed change.

Not a good stack, the stepsize set at 2um is evidently inadequate and I did not cross the polarisers, like an idiot. Either way, its performance is similar to Wemacro’s original stepper motor, and secured confidence in me. Made a quick background replacement, the drop shadow and vignette effects were added during post processing.

References

Prior Optiscan ES11 manual (installation of the focus drive onto microscopes): https://www.prior.com/product/optiscan-es11-controller

Wemacro Webstore: https://www.wemacro.com/?product_cat=extreme-macro&paged=1

Lin Engineering motor naming scheme (at the bottom of the page): https://www.linengineering.com/products/stepper-motors/hybrid-stepper-motors/4418-series/4418S-01

1 thought on “Improving the Wemacro Micromate (Part 1/2)”